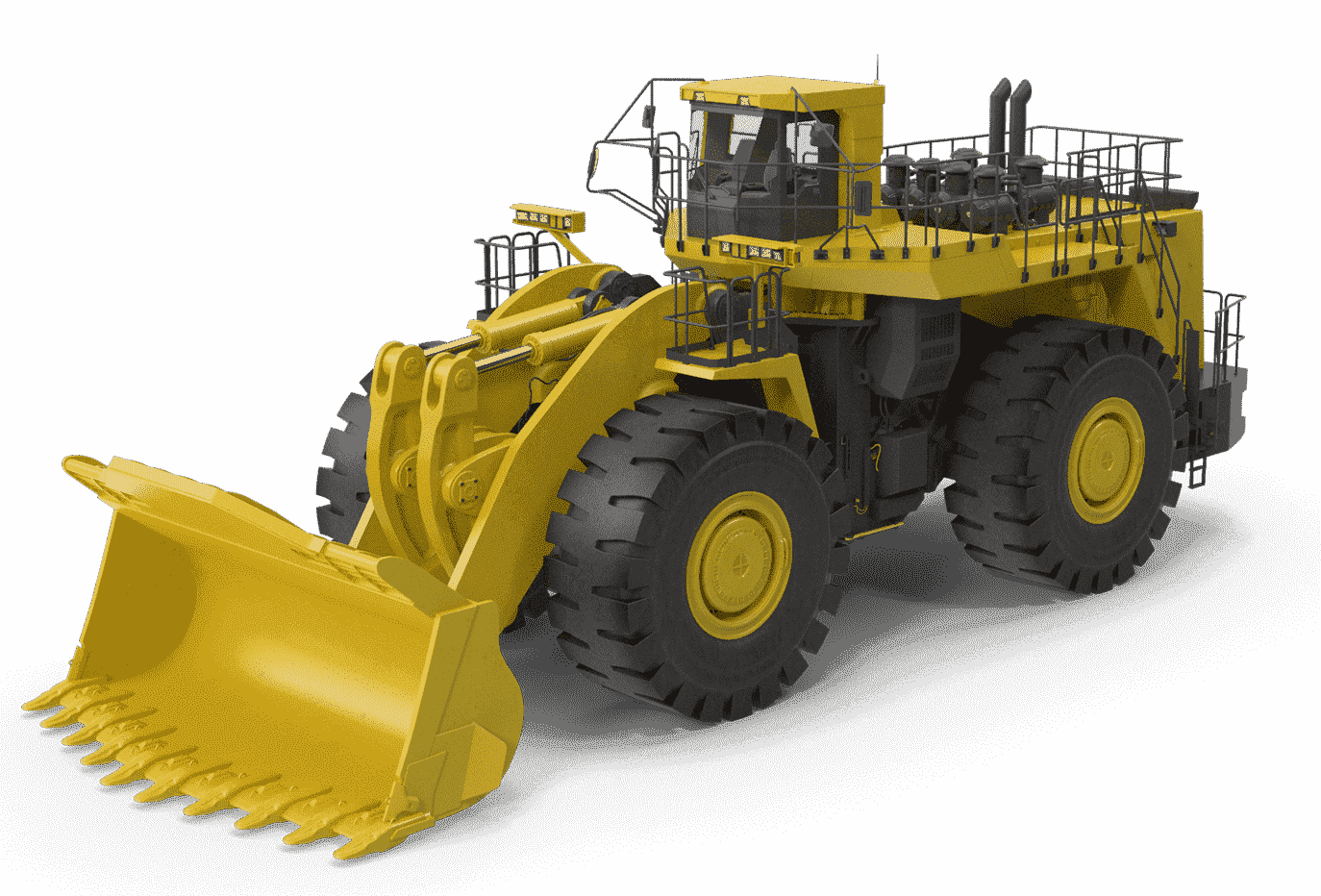

Hydraulic pumps are the unsung heroes of the mechanical world, fascinating in their design and crucial in their application. These amazing devices convert mechanical energy into hydraulic energy, powering a vast array of machinery from construction equipment to your car’s brake system.

Understanding the different types of hydraulic pumps available at Exclusive Hydraulics, especially the distinction between open and closed-loop hydraulic pumps, is essential for anyone looking to harness the full potential of this technology.

Understanding Hydraulic Pumps

At the heart of countless industrial and mechanical operations lie hydraulic pumps, the unsung heroes seamlessly bridging the gap between the mechanical and hydraulic worlds. With their intricate design and pivotal role, these remarkable devices adeptly convert mechanical energy into hydraulic energy. This transformation is the lifeblood of a myriad of machinery, ranging from the heavy-duty equipment that shapes our infrastructure to the critical brake systems in our vehicles. Grasping the variety of hydraulic pumps available is crucial, particularly in understanding the nuances between open and closed-loop hydraulic pumps. This knowledge is indispensable for those keen on maximising the capabilities of hydraulic technology.

Hydraulic pumps, by their very nature, are defined by their ability to manage pressure and facilitate fluid flow within a system. This capability is not just about moving fluid from point A to point B; it’s about creating the power necessary to perform a vast spectrum of tasks. The elegance of hydraulic systems lies in their proficiency to amplify force in a straightforward yet efficient manner. This attribute of hydraulic pumps to efficiently move fluid while maintaining control over pressure and flow is what makes them integral to various applications.

The Heart Of Hydraulics

The engineering behind the operation of a hydraulic pump is nothing short of fascinating. Drawing fluid from a reservoir and subsequently pressurising it within a hydraulic system, these pumps offer a degree of control and power output that is remarkable for their size. It is this unparalleled efficiency that positions hydraulic pumps as essential components across a wide range of industries. Whether it is operating complex machinery or providing the force needed for simpler mechanical tasks, the role of hydraulic pumps cannot be overstated.

Types Of Hydraulic Pumps

The realm of hydraulic pumps is diverse, with several types designed to meet the needs of different applications. However, our focus centers on the two primary categories that stand out due to their distinctive operation and benefits: open-loop and closed-loop hydraulic pumps. Each type brings its advantages and is tailored for specific situations, making the distinction between them critical for effective application.

Open Loop Hydraulic Pumps

Open-loop hydraulic systems epitomise simplicity and cost-effectiveness. In these systems, the hydraulic pump circulates fluid from a reservoir, through the machinery, and then back to the reservoir. This continuous cycle is straightforward, minimising complexity and reducing costs. Such a system is particularly well-suited for applications where precise control over movement is less critical, making open-loop hydraulic pumps a versatile choice for various tasks.

Closed Loop Hydraulic Pumps

In contrast, closed-loop hydraulic systems represent a more controlled and efficient approach. These systems keep the fluid in a closed circuit, only returning it to the reservoir to compensate for any losses. This design ensures a higher level of control and efficiency, making closed-loop hydraulic pumps ideal for applications that demand precise speed and positioning. The ability to maintain tight control over the system’s operation without sacrificing efficiency is what sets closed-loop pumps apart, highlighting their significance in more demanding applications.

When it comes to efficiency and application, both open and closed-loop systems have their place. Open loops, with their simplicity and cost-effectiveness, are perfect for applications where fine control is less critical. Closed loops, however, shine in situations where efficiency and precise control are paramount.

Efficiency And Application

When it comes to hydraulic pumps, the decision between an open loop and a closed loop system is largely dictated by the specific requirements of the application at hand. Closed loop hydraulic pumps, despite their increased complexity and cost, are renowned for providing superior efficiency and control. This makes them the preferred option for applications that demand high performance and precision. These systems are adept at maintaining consistent pressure and flow rates, essential for operations where even the slightest variance could lead to significant issues. On the other hand, open-loop hydraulic pumps, while not as efficient as their closed counterparts, still play a crucial role in many settings due to their simplicity and lower initial investment.

Looking for hydraulic repairs? Try us out!

Cost Implications

Cost considerations are paramount when choosing between open and closed-loop hydraulic pump systems. The advanced performance and control offered by closed loop systems come at a price, attributed to their complexity and the necessity for additional components. This can make them a more costly option upfront. However, it is important to weigh these initial costs against the potential for increased efficiency and reduced operational costs over time. Open-loop hydraulic pumps, with their simpler design and fewer components, often present a more budget-friendly option initially but may not offer the same level of performance or efficiency as closed loop systems.

How To Choose The Right Pump

Selecting the appropriate hydraulic pump for your needs involves a thorough understanding of your system’s requirements, encompassing power, efficiency, control, and cost. Consulting with experts in the field can provide invaluable insights, helping you navigate the complexities of hydraulic systems. By carefully assessing these factors, you can identify which type of hydraulic pump—be it open loop or closed loop—best aligns with your application’s demands. This decision is critical not only for ensuring optimal performance but also for maximizing the longevity and reliability of your hydraulic system.

Maintenance Tips

The longevity and efficiency of hydraulic pumps are heavily influenced by regular maintenance. Proper upkeep, including routine checks and timely maintenance, is essential for preventing operational downtime and avoiding costly repairs. For both open-loop and closed-loop hydraulic pumps, establishing a maintenance schedule that includes checking for leaks, monitoring fluid levels, and replacing worn components can significantly extend the life of the pump and ensure it continues to operate at peak efficiency. Addressing common issues promptly, before they escalate, can save both time and money in the long run.

The Future Of Hydraulics

The landscape of hydraulic pumps is continuously evolving, with advancements in technology driving improvements in efficiency, power, and versatility. Innovations in materials, design, and control systems are paving the way for next-generation hydraulic pumps that can meet the increasingly stringent demands of modern applications. These developments promise not only to enhance the performance of hydraulic pumps but also to open new possibilities for their use in various industries, from manufacturing to renewable energy.

Hydraulic pumps embody a remarkable fusion of power, efficiency, and versatility that sets them apart from other mechanical systems. Whether navigating the choice between open-loop and closed-loop systems or considering the specific requirements of your application, understanding the capabilities and limitations of each type of hydraulic pump is essential. As critical components in a wide range of machinery and equipment, hydraulic pumps play an indispensable role in powering our modern world. Their ongoing development and refinement ensure that they will continue to be a key driver of innovation and efficiency across numerous industries.