Hydraulic pumps are the unsung heroes of modern engineering – powering everything from construction equipment to manufacturing systems with precision and strength. But even the most robust systems will fail if proper hydraulic pump maintenance is neglected.

Pump failure can cost thousands in repairs, hours of unplanned downtime, and serious production setbacks. The good news? With a few expert-approved techniques, you can significantly extend pump life and avoid costly disruptions.

At Exclusive Hydraulics and Engineering, we have seen it all – from worn-out seals due to oil contamination, to full pump breakdowns caused by overheating. In this guide, we will share six powerful, practical ways to protect your hydraulic pump, boost system longevity, and ensure peak performance in 2025 and beyond.

How To Boost Hydraulic Pump Maintenance For A Longer Life

🔧 1. Prioritise Clean Hydraulic Oil

One of the most overlooked yet critical aspects of hydraulic pump maintenance is oil cleanliness.

Contaminated hydraulic oil is the number one cause of premature pump failure. Dust, dirt, metal particles, and water can enter the system and wear down pump components, damage valves, and destroy seals. Clean oil equals a healthy system.

Here’s how to protect your system:

- Perform regular oil analysis to monitor particle levels, moisture, and viscosity.

- Use the correct ISO VG-rated hydraulic oil specified for your machinery.

- Store oil properly and keep it sealed, cool, and away from moisture.

- Always filter new oil before filling the tank to remove transport contaminants.

📌 Expert Tip: Install return-line and pressure-line filters rated to catch particles as small as 3 to 10 microns. This small step can make a massive difference.

💡 Need help choosing or testing the right hydraulic oil? Contact Exclusive Hydraulics for expert guidance or oil testing solutions.

🌡️ 2. Maintain Ideal Operating Temperatures

Overheating is a silent killer of hydraulic systems.

When oil temperatures exceed the recommended range (typically 35°C to 60°C), the oil begins to degrade rapidly, reducing its lubricating qualities and damaging seals and internal pump surfaces. Excessive heat can also cause cavitation, where vapor bubbles implode inside the pump, leading to internal erosion.

Ensure proper temperature control by:

- Installing thermal sensors for real-time heat monitoring.

- Inspecting fans, coolers, and heat exchangers for dust or mechanical failure.

- Ensuring the reservoir is clean and allows proper airflow.

If your system frequently runs hot, consider switching to a higher-grade synthetic hydraulic fluid, which handles elevated temperatures better and extends pump life and reduces hydraulic repairs.

🔗 External Reference: Managing hydraulic system heat — Hydraulics & Pneumatics

⚖️ 3. Avoid Excessive Load Cycles

Every time your system powers up or changes direction under load, it stresses the pump. Over time, excessive start-stop cycles, pressure spikes, or flow surges will wear down components like pistons, bearings, and housings – all of which can shorten the life of your hydraulic pump maintenance significantly.

Minimise wear and energy waste by:

- Sizing the pump correctly for expected load demands and hydraulic pump maintenance.

- Avoiding “deadheading,” where the pump runs but fluid has nowhere to go.

- Using pressure relief valves to buffer sharp pressure changes.

- Installing accumulators to absorb load shocks and reduce demand peaks.

Well-managed cycling reduces component fatigue and promotes smoother operation across your entire hydraulic system.

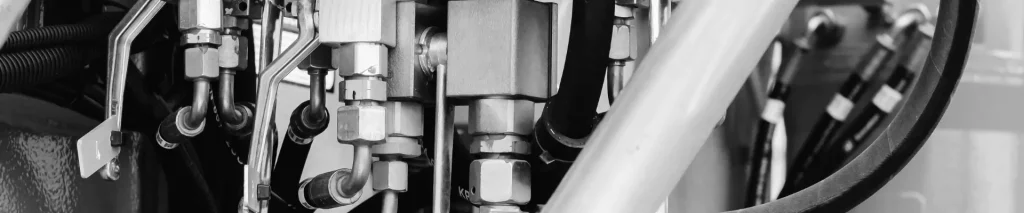

🧼 4. Use High-Quality Filtration Systems

A clean system is a productive system – and filtration is your front line of defense.

Even the best hydraulic oil can not protect your system if debris and contamination are allowed to circulate. Without proper filtration, tiny particles can score metal surfaces, clog passages, and accelerate pump wear. Effective hydraulic pump maintenance demands superior filtration.

Your system should include:

- Suction filters to guard the pump inlet.

- Return-line filters to clean oil returning to the tank.

- Pressure-line filters to protect downstream components.

- Breather filters to block airborne particles from entering through the reservoir.

📌 Best practice: Monitor pressure differential across filters and replace them according to manufacturer recommendations – or sooner if you notice pressure drops or alarms.

Need an upgrade or unsure of your filter spec? Exclusive Hydraulics can help you assess and install the right filtration system for your equipment.

🔍 5. Implement A Predictive Maintenance Schedule

Gone are the days of waiting for a breakdown to act. Predictive maintenance is the new gold standard in hydraulic pump care.

Instead of relying solely on calendar-based servicing, predictive systems monitor pump health in real time. This data-driven approach can detect subtle warning signs long before failure occurs, saving your company time, money, and stress.

Tools to consider include:

- Vibration sensors to detect imbalance or wear.

- Thermal imaging to reveal heat concentration issues.

- Flow meters to identify restriction or loss.

- Oil quality sensors for moisture and oxidation tracking.

Keep digital or physical logs of all maintenance activities, pressure changes, filter swaps, and system anomalies. These logs offer invaluable data to forecast future needs.

✅ Bonus: Exclusive Hydraulics offers tailored system health checks, predictive maintenance scheduling, and component upgrades for all major hydraulic applications.

🧰 6. Invest In Professional Installation & Correct Start-Up

Many pump failures do not occur years down the line – they start the very first day.

Incorrect installation, improper start-up, or skipped commissioning steps can spell disaster for your hydraulic system. Dry starts, unaligned shafts, or air pockets can cause catastrophic internal damage.

Always ensure that you:

- Use trained and certified technicians for installation.

- Bleed the system thoroughly before start-up.

- Torque bolts and couplings to specification (not by guesswork).

- Double-check directional flow, pressure settings, and pump rotation.

💡 Pro Tip: Avoid DIY assembly. Call in a certified team like Exclusive Hydraulics to guarantee a flawless, long-lasting install.

🧩 Bonus Tip: Match Your System Components

Hydraulic pump maintenance is complex – and each component must work in harmony. Mixing pumps, valves, and motors without verifying compatibility leads to friction, inefficiency, and mechanical stress.

When choosing components, ensure they are:

- Rated for the same pressure and flow ranges.

- Sized correctly for your application.

- Made from compatible materials (especially when working with special fluids).

An imbalanced system leads to premature wear and reduced efficiency – a common oversight that proper hydraulic pump maintenance can easily prevent.

✅ Final Thoughts: Protect Your Pump, Protect Your Productivity

Your hydraulic pump maintenance is the heart of your system – and like any heart, it needs routine care, proper lubrication, and a stress-free environment to operate effectively.

Let us recap the six expert-approved techniques to extend your hydraulic pump’s life:

- Keep your oil clean and contaminant-free.

- Maintain safe and stable operating temperatures.

- Avoid harmful load cycles and pressure spikes.

- Use efficient, well-placed filtration systems.

- Adopt predictive maintenance practices.

- Install and start up your system professionally.

Each of these actions may seem small – but together, they form a powerful maintenance strategy that dramatically improves the longevity, safety, and performance of your hydraulic equipment.

Whether you are running mining, manufacturing, or heavy-duty agricultural machinery, hydraulic pump maintenance is your first line of defense against downtime and disaster.

🔧 Work With The Experts In Hydraulic Pump Maintenance

At Exclusive Hydraulics and Engineering, we offer premium hydraulic solutions, including:

- On-site inspections and system audits.

- Oil testing and analysis.

- Component replacements and repairs.

- Custom installations and maintenance plans.

Ready to reduce downtime and boost system longevity? Hydraulic pump maintenance is our top priority!

👉 Contact us today or visit exclusivehydraulics.co.za to explore our full range of services.

Let us keep your hydraulic pump maintenance running at its best — longer.

Read More

5 Powerful Ecohydraulics Innovations Every Engineer Should Know.