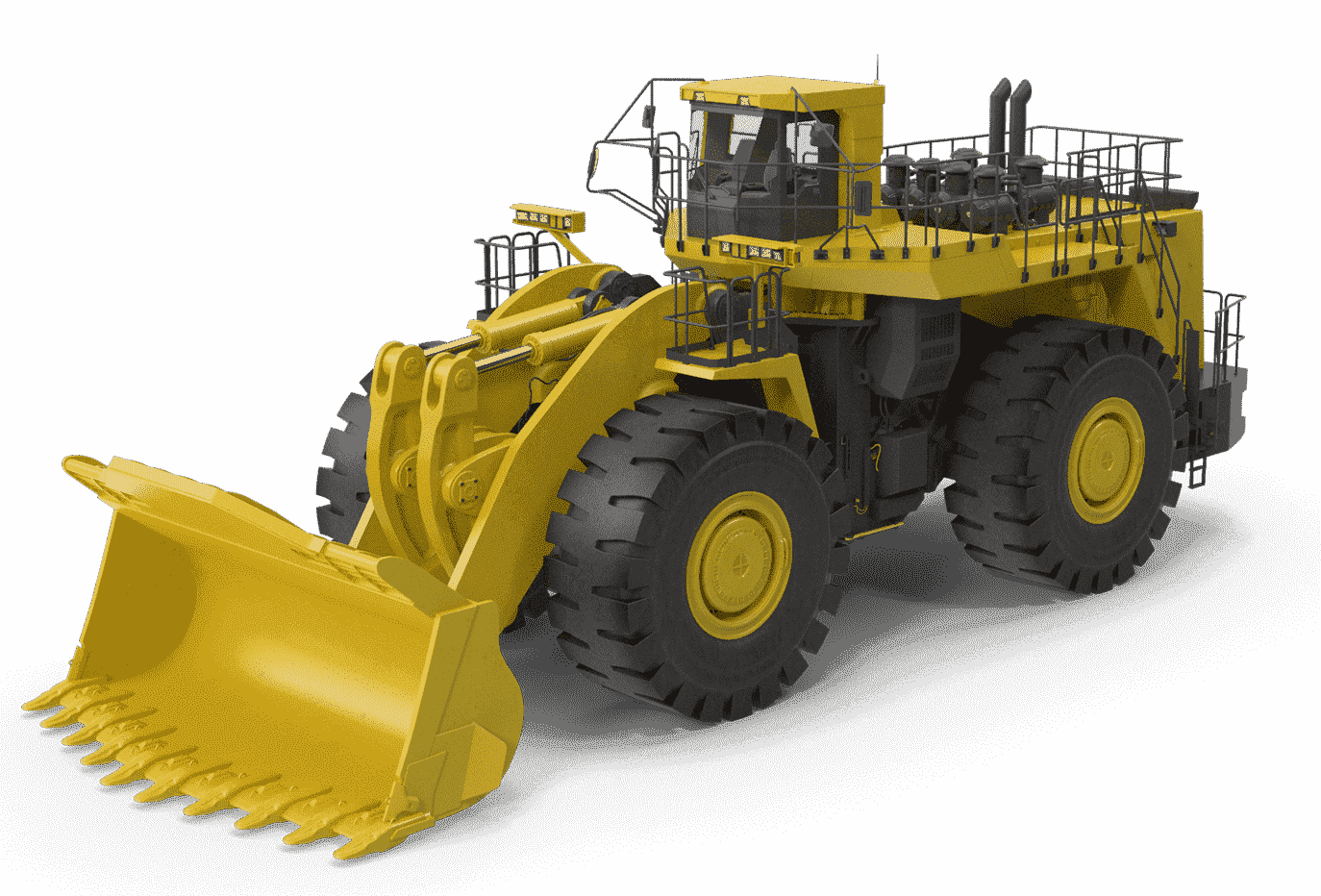

At Exclusive Hydraulics & Engineering, we pride ourselves on over 25 years of experience in hydraulic repairs and earthmoving bucket repairs. Our expertise has allowed us to develop innovative techniques that extend the lifespan of your equipment, reduce downtime, and save costs. In this article, we introduce our three new earthmoving bucket repair techniques that promise to enhance the performance and durability of your earthmoving machinery.

The Importance of Earthmoving Bucket Repair

Earthmoving buckets are subjected to extreme conditions and heavy loads, which can lead to significant wear and tear. Regular maintenance and timely repairs are crucial to ensure optimal performance and longevity. Effective earthmoving bucket repair not only prevents unexpected breakdowns but also enhances the efficiency of your operations.

Why Choose Exclusive Hydraulics & Engineering?

With a quarter-century of industry experience, Exclusive Hydraulics & Engineering is your trusted partner for all hydraulic and earthmoving bucket repair needs. Our team of skilled technicians is dedicated to delivering high-quality repairs using the latest techniques and technologies. Our commitment to excellence ensures that your equipment performs reliably and efficiently.

Technique 1: Advanced Welding Processes

The Role of Welding in Bucket Repair

Welding is a fundamental technique in earthmoving bucket repair. It involves joining metal parts by melting the base metal and adding a filler material to form a strong bond. Advanced welding processes are essential for repairing cracks, reinforcing weak points, and restoring the structural integrity of the bucket.

Our Advanced Welding Techniques

At Exclusive Hydraulics & Engineering, we utilize state-of-the-art welding techniques to ensure the highest quality repairs. Our advanced welding processes include:

- MIG Welding (Metal Inert Gas Welding): This technique uses a continuous wire feed as an electrode and an inert gas to shield the weld. MIG welding is highly effective for repairing large sections and providing strong, durable welds.

- TIG Welding (Tungsten Inert Gas Welding): TIG welding uses a tungsten electrode to produce precise and clean welds. This technique is ideal for intricate repairs and areas requiring high precision.

- Arc Welding: Arc welding uses an electric arc to melt the base metal and filler material, creating a robust bond. It is versatile and suitable for a wide range of repair applications.

Benefits of Advanced Welding

- Enhanced Durability: Our advanced welding techniques ensure that repairs are durable and can withstand heavy loads and harsh conditions.

- Improved Performance: Properly welded buckets perform better and have a longer service life, reducing the need for frequent replacements.

- Cost-Effective: High-quality welding minimizes the risk of future damage, saving you money on additional repairs and replacements.

Technique 2: Hardfacing for Increased Wear Resistance

What is Hardfacing?

Hardfacing is a specialized technique used to enhance the wear resistance of metal surfaces. It involves applying a layer of hard material to the surface of the bucket to protect it from abrasion, impact, and other forms of wear. Hardfacing is particularly beneficial for earthmoving buckets that operate in abrasive environments.

Our Hardfacing Techniques

Exclusive Hydraulics & Engineering employs cutting-edge hardfacing techniques to extend the lifespan of your earthmoving buckets. Our methods include:

- Overlay Welding: This technique involves depositing a layer of wear-resistant material onto the bucket’s surface. The overlay material is selected based on the specific wear conditions the bucket will encounter.

- Thermal Spraying: Thermal spraying involves applying a coating of wear-resistant material using a high-temperature spray gun. This method is effective for achieving uniform coverage and protecting large surface areas.

- Brazing: Brazing uses a filler metal with a lower melting point than the base metal to join or coat the surface. It provides excellent wear resistance and is suitable for specific applications where traditional welding is not feasible.

Benefits of Hardfacing

- Extended Service Life: Hardfacing significantly increases the wear resistance of your buckets, prolonging their service life.

- Reduced Downtime: Enhanced durability means fewer repairs and replacements, leading to less downtime and more productive operations.

- Cost Savings: By preventing excessive wear and tear, hardfacing reduces maintenance costs and extends the intervals between repairs.

Technique 3: Precision Machining for Accurate Repairs

The Importance of Precision in Bucket Repair

Precision machining is crucial for ensuring that repaired components fit and function correctly. Accurate machining restores the original dimensions and specifications of the bucket, allowing it to operate efficiently and safely.

Our Precision Machining Techniques

At Exclusive Hydraulics & Engineering, we utilize advanced precision machining techniques to deliver high-quality repairs. Our capabilities include:

- CNC Machining (Computer Numerical Control): CNC machining uses computer-controlled tools to achieve precise dimensions and tolerances. This technique is ideal for complex repairs and high-precision components.

- Manual Machining: Our skilled technicians also perform manual machining for specific repairs that require a hands-on approach. This technique allows for fine adjustments and custom solutions.

- Surface Grinding: Surface grinding ensures that repaired surfaces are smooth and free from imperfections. It is essential for achieving optimal performance and longevity.

Benefits of Precision Machining

- Accurate Repairs: Precision machining ensures that repaired components meet original specifications, resulting in better performance.

- Improved Efficiency: Accurate repairs reduce friction and wear, enhancing the overall efficiency of the bucket.

- Enhanced Safety: Properly machined components fit correctly and operate safely, reducing the risk of equipment failure.

Why Choose Exclusive Hydraulics & Engineering?

Exclusive Hydraulics & Engineering stands out in the industry due to our commitment to quality, innovation, and customer satisfaction. Here’s why you should choose us for your earthmoving bucket repair needs:

- Experienced Technicians: Our team has over 25 years of experience in hydraulic and earthmoving bucket repairs, ensuring expert service and high-quality results.

- State-of-the-Art Technology: We invest in the latest tools and technologies to provide advanced repair techniques and superior outcomes.

- Customized Solutions: We understand that each repair job is unique, and we tailor our techniques to meet your specific needs and requirements.

- Comprehensive Services: In addition to earthmoving bucket repairs, we offer a wide range of hydraulic repair services, making us your one-stop shop for all equipment maintenance needs.

Conclusion

The power of advanced repair techniques cannot be underestimated when it comes to maintaining and enhancing the performance of your earthmoving equipment. At Exclusive Hydraulics & Engineering, we are dedicated to providing top-notch repair services using the latest techniques and technologies. Our advanced welding processes, hardfacing techniques, and precision machining ensure that your buckets are restored to optimal condition, offering durability and reliability.

Ready to experience the benefits of our innovative earthmoving bucket repair techniques? Contact Exclusive Hydraulics & Engineering today to learn more about how we can help extend the life of your equipment and improve your operational efficiency. Visit our social channels for more information and to see our full range of services.

Trust us with your repair needs and let our expertise keep your equipment performing at its best.