Hydraulic systems downtime is one of the most frustrating challenges faced by operators across industries like mining, agriculture, construction, and manufacturing. When a hydraulic system fails, it causes delays, financial losses, and operational chaos. But what if there were smart, simple ways to reduce this frustrating downtime?

At Exclusive Hydraulics and Engineering in Johannesburg, we believe prevention is better than cure. With years of hands-on experience in hydraulic repairs, rebuilds and custom solutions, we have compiled these 7 amazing hacks that actually reduce hydraulic systems downtime. Implement them and you will not only protect your systems – you will boost your productivity and bottom line.

Your hydraulic system does not hate you. It is just tired. These hacks will keep it happy and humming.

No More Hydraulic Systems Downtime, Here’s How

1. Embrace Predictive Maintenance

Many companies still rely on reactive maintenance – waiting until something fails. But by then, it is too late. One of the smartest ways to cut hydraulic systems downtime is by switching to predictive maintenance.

Hack: Install condition monitoring tools to continuously track temperature, pressure, fluid cleanliness, and other vital parameters. These tools detect early warning signs of wear or failure long before a breakdown occurs.

Why it matters: Predictive maintenance helps avoid sudden breakdowns, allowing you to plan repairs and replacements with zero disruption to workflow.

✅ Want help setting up a predictive maintenance strategy? Explore our services today.

2. Perform Regular Hydraulic Fluid Analysis

Hydraulic fluid is the heart of your system. Contaminated or degraded fluid is the leading cause of hydraulic systems downtime. If you do not monitor your fluid, you are flying blind.

Hack: Send your hydraulic oil for lab testing at regular intervals. Look for signs of:

- Water contamination.

- Acid buildup.

- Viscosity changes.

- Particle ingress.

This proactive step can extend component life and reduce hydraulic systems downtime significantly.

💡 Book your next hydraulic oil test with our expert team. Contact us here.

3. Upgrade To Advanced Filtration

Dirty oil destroys systems. In fact, studies show that up to 80% of hydraulic failures are caused by fluid contamination. Reducing this dramatically cuts hydraulic systems downtime.

Hack: Use high-efficiency filters capable of removing particles as small as 3 microns. Replace filters before they are clogged – not after a warning light appears.

Also, consider adding auxiliary filtration systems for systems under heavy load or in harsh environments.

🧰 Need help selecting the right filters for your machines? Visit our Service Exchange Components page.

4. Tame The Heat: Control Operating Temperatures

Excessive heat can silently destroy seals, hoses, and fluid integrity – leading to costly hydraulic systems downtime.

Hack: Use heat exchangers, thermostats, and adequate ventilation to regulate your hydraulic system temperature. Always aim to stay within the optimal operating range of 35°C to 60°C.

Bonus Tip: Install digital temperature gauges to keep a real-time eye on your system’s health.

🔥 Overheating issues? Let us perform a thermal assessment. Book a system check-up today.

5. Train Your Operators Effectively

Even the best machines break down when handled poorly. Skilled operators are your first line of defence against hydraulic systems downtime.

Hack: Provide training sessions that teach operators:

- How to identify early warning signs.

- Safe operating procedures.

- Best practices for startup and shutdown.

Trained staff will notice abnormal vibrations, noise, or temperature spikes before they turn into major failures.

🎓 We offer tailored operator training and onsite support. Enquire today: Contact Exclusive Hydraulics

6. Use OEM-Approved Parts Only

When replacing hydraulic components, quality matters. Using sub-standard or incorrect parts is a fast track to hydraulic systems downtime.

Hack: Always opt for OEM (Original Equipment Manufacturer) components. These are engineered to meet exact specifications and maintain your system’s integrity.

Avoid generic parts – even if they seem cheaper. They wear out faster, leak under pressure, and cause frequent maintenance issues.

🔧 We supply and install genuine parts for all major hydraulic systems. Shop quality components.

7. Maintain Digital Service Records

Hydraulic systems downtime often stems from missed maintenance windows or lack of tracking. You cannot improve what you do not measure.

Hack: Ditch the paper logs. Switch to a digital maintenance tracking system to record:

- Service intervals.

- Oil changes.

- Parts replaced.

- Notes from technicians.

Digital records help you spot patterns, plan preventive tasks, and avoid recurring problems.

Fact: Companies using digital maintenance tracking reduce hydraulic systems downtime by up to 30%.

Need help modernising your records? Reach out to our team for digital setup support.

BONUS: Build A Long-Term Partnership With Hydraulic Experts

Hydraulic systems downtime does not have to be inevitable. With the right support, you can run your operations more reliably and efficiently.

That is where we come in. At Exclusive Hydraulics and Engineering, we are more than just a service provider – we are your go-to partner for all things hydraulic.

From precision rebuilds to on-site diagnostics, we are trusted by businesses across Johannesburg and beyond.

✅ Explore our full list of Services.

✅ Need urgent help? Contact us today!

Hydraulic Systems Downtime Is A Headache You Can Avoid

Hydraulic systems downtime can be a major headache – but it does not have to be. By applying these seven smart hacks, you can stay ahead of breakdowns, extend equipment life, and boost productivity.

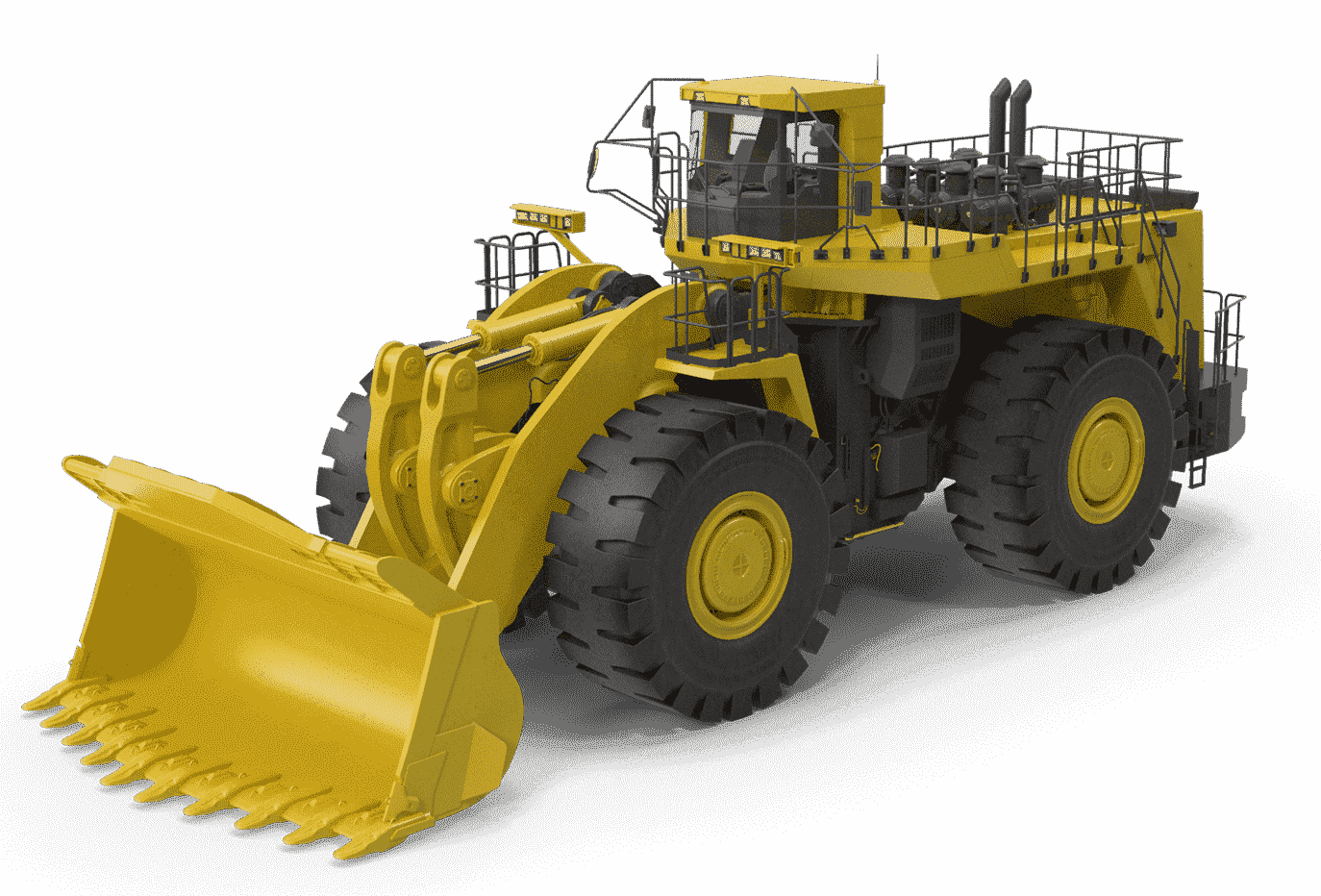

Whether you are managing heavy-duty mining gear or agricultural equipment, every second of uptime counts. Do not wait for failure. Be proactive.

Ready to future-proof your systems?

🔧 Call Exclusive Hydraulics and Engineering today. Let us keep your systems strong, efficient, and ready for anything.

Hydraulic Systems Downtime? Not On Our Watch.

Read More

Why Is My Hydraulic Pump Failing? 5 Annoying Causes You Should Know Now.